For apparel brand developers, textile engineers, and strategic procurement specialists, the choice between knit and woven fabrics is a foundational decision impacting product performance, consumer satisfaction, and brand...

READ MORECustom Liquid Ammonia Printing Fabric

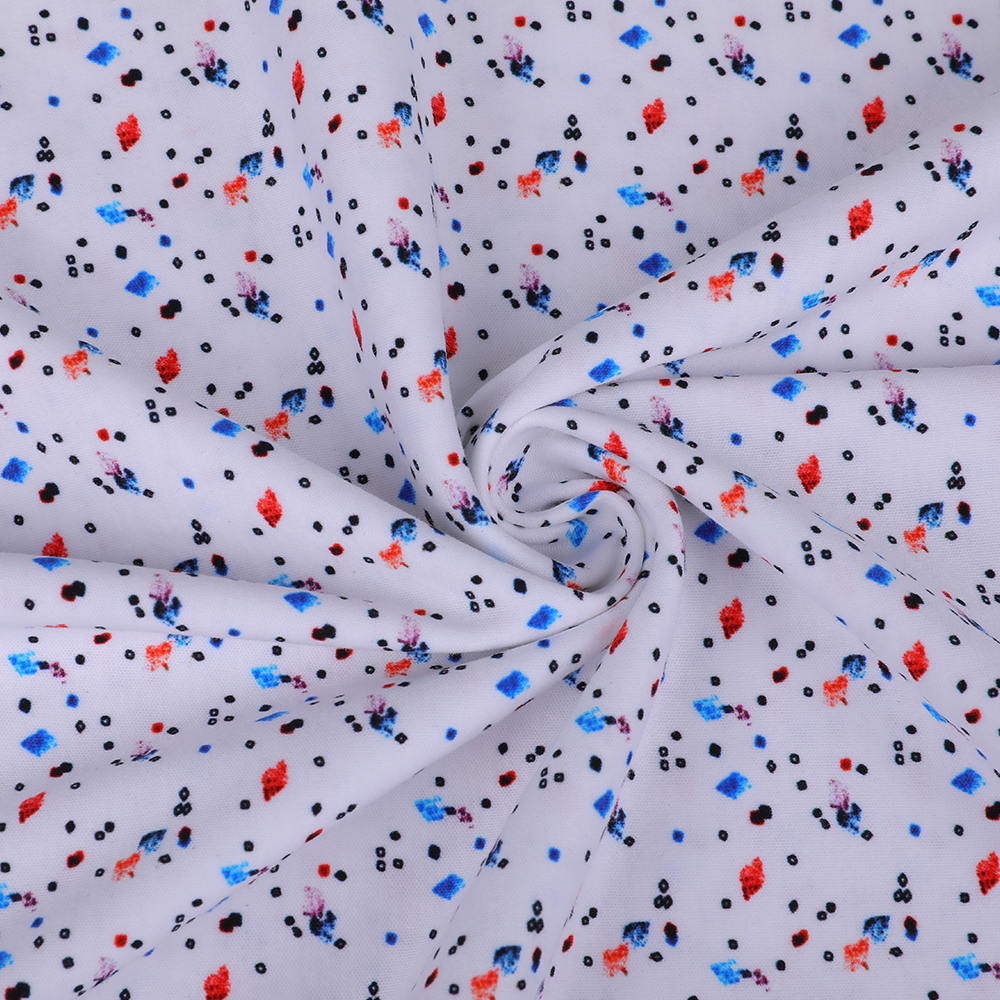

The liquid ammonia printing series fabrics adopt advanced liquid ammonia printing technology, which not only retains the original softness and breathability of the fabric but also achieves good brightness and durability in color performance. In the process of liquid ammonia printing, the fabrics undergo precise pre-treatment to ensure that every inch of fiber can evenly absorb the dye. Then, under a strictly controlled temperature and pressure environment, liquid ammonia acts as a powerful medium to help the dye penetrate the fiber to achieve a delicate and uniform coloring effect. This step not only greatly improves the saturation and firmness of the color, but also gives the fabric a delicate texture and rich layers like a work of art. The rapid volatilization characteristics of liquid ammonia ensure the high efficiency and energy saving of the production process and reduce the impact on the environment. This series of fabrics is widely used in many fields such as clothing, home decoration, and creative design. In clothing, whether it is a light and elegant dress or a comfortable and close-fitting casual wear, liquid ammonia printed fabrics can become a good choice for fashion gurus with their good color performance and wearing experience. Liquid ammonia printed series fabrics also have good washability and wear resistance. Even after repeated washing and friction, they can still maintain the bright colors and texture of the fabrics, so that each product can be kept as new for a long time.

-

Comfortable Eco-friendly Stretch Digital Printing Spandex Jacquard Skirt T-shirt Fabric

-

Breathable Stretch Digital Printing LA Liquid Ammonia Interlock Fabric Suitable for T-shirts

-

Spandex Jersey Breathable Stretch Digital Printing Mercerized Comfortable T-shirt Fabric

-

Interlock Eco-friendly Stretch Liquid Ammonia Digital Printing LA Fabric Suitable for Skirts

-

-

For apparel manufacturers and brand owners, the decision of where and how to source cotton shirt fabric wholesale is a fundamental strategic choice that directly impacts product quality, cost structure, brand reputation,...

READ MORE -

In the global garment industry, the challenge for engineers lies in balancing aggressive cost targets with the mechanical durability required for consumer satisfaction. The production of cheap knit fabric often carries a...

READ MORE

Why are the color of liquid ammonia printing fabrics lasting and bright?

The reason why the color of liquid ammonia printing fabrics is long-lasting and bright is mainly due to the precise control of the fiber structure by liquid ammonia treatment technology. This technology significantly improves its ability to adsorb dyes by changing the chemical properties of the fiber surface, allowing the dye to adhere more firmly to the fibers. During the liquid ammonia treatment, the fiber structure is finely adjusted, which not only enhances the color fastness of the fabric, but also allows dye molecules to penetrate deep into the fiber, thus making the printed colors more vivid and long-lasting, and is not easy to fade due to repeated wear and washing.

Liquid ammonia treatment makes the fiber surface smoother, reducing friction between the fibers while improving the density and uniformity of the fabric. This structural improvement helps the dye to be evenly distributed on the fabric, avoiding the color unevenness and fading problems caused by the inadequate penetration of the dye in traditional printed fabrics. Therefore, liquid ammonia printing fabrics can maintain color stability for a long time and are not prone to discoloration or fading during the washing process.

In addition, liquid ammonia treatment also enhances the UV resistance of the fabric. By improving the density and structure of the fibers, liquid ammonia treatment makes the fabric more sensitive to the external environment, especially the ability to reflect ultraviolet rays is significantly improved. This effectively reduces the damage to the dye by UV light and provides an additional protective layer for liquid ammonia printing fabrics, allowing them to maintain bright colors even when exposed to sunlight for a long time.

Liquid ammonia treatment can also enhance the surface gloss of the fabric. This gloss is not achieved through chemical coatings or coatings, but a natural and uniform gloss that makes the color look brighter and deeper. This effect is especially important for high-end fashion clothing, and designers often rely on liquid ammonia printing fabrics to show more vivid and modern print designs. Compared with traditional fabrics, the surface of liquid ammonia printing fabrics is more delicate, which can better present complex printing patterns and enhance the overall texture of the fabric.

This fabric is not only suitable for everyday clothing, but also especially suitable for sportswear, outdoor gear and high-end fashion apparel. The breathability and comfort of liquid ammonia printing fabrics also provide guarantees for long-term wear. The clothes not only do not appear thick, but also enhance the wearer's experience.

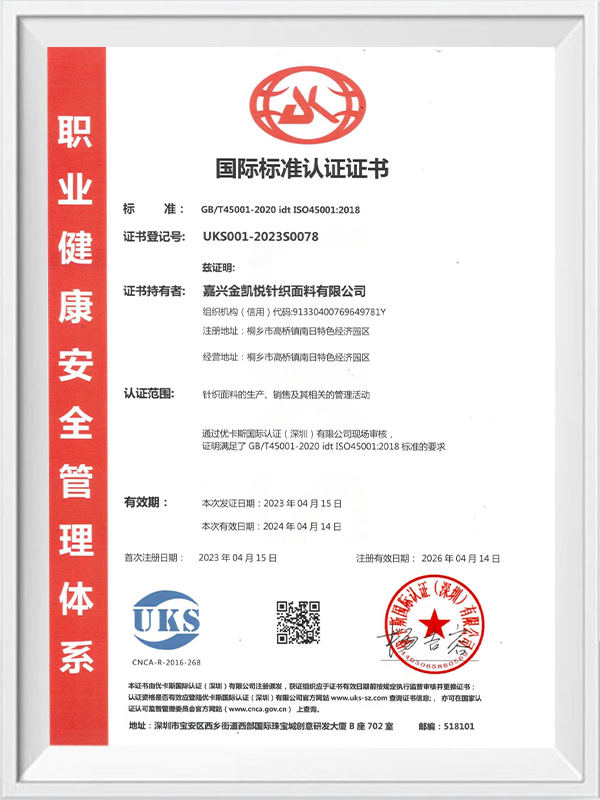

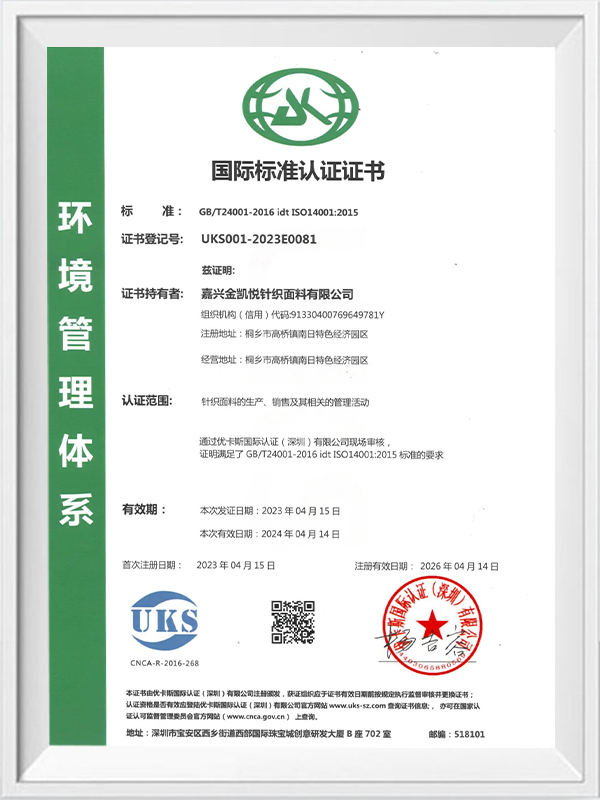

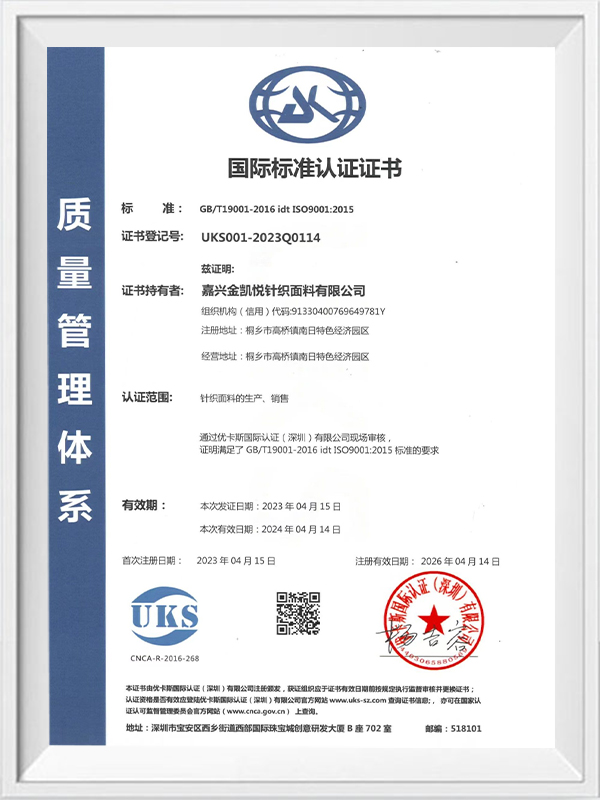

In the research and development and application of liquid ammonia treatment technology, some leading textile companies have provided high-quality liquid ammonia printing fabrics to the market through years of technical accumulation and innovation. Taking Jiaxing Jinkaiyue Knitted Fabric Co., Ltd. as an example, this company is committed to the research and development of high-end fiber materials, covering a variety of high-end fabrics such as mulberry silk, long-length cotton, wool, cashmere, etc., and combined with liquid ammonia treatment technology, the fabric is more in line with the needs of modern consumers. Through technological innovation, Jinkaiyue's liquid ammonia printing fabrics not only have excellent color retention capabilities, but also have comfort, breathability and durability. They are widely used in high-end fashion, sportswear, casual clothing and underwear fields. Whether it is brand customization or personalized design, Jinkaiyue can provide customers with customized solutions to ensure that each fabric maintains bright colors while meeting the dual needs of comfort and durability.

liquid ammonia printing fabrics are becoming an important choice in the textile industry with their long-lasting colors, excellent performance and a wide range of application scenarios. With the continuous advancement of technology and the growth of market demand, liquid ammonia treatment technology will continue to promote textiles to develop in a higher-end and environmentally friendly direction, bringing consumers a better wearing experience.

English

English 日本語

日本語 中文简体

中文简体