For apparel brand developers, textile engineers, and strategic procurement specialists, the choice between knit and woven fabrics is a foundational decision impacting product performance, consumer satisfaction, and brand...

READ MORECustom Machine Washable Silk Knitting Fabric

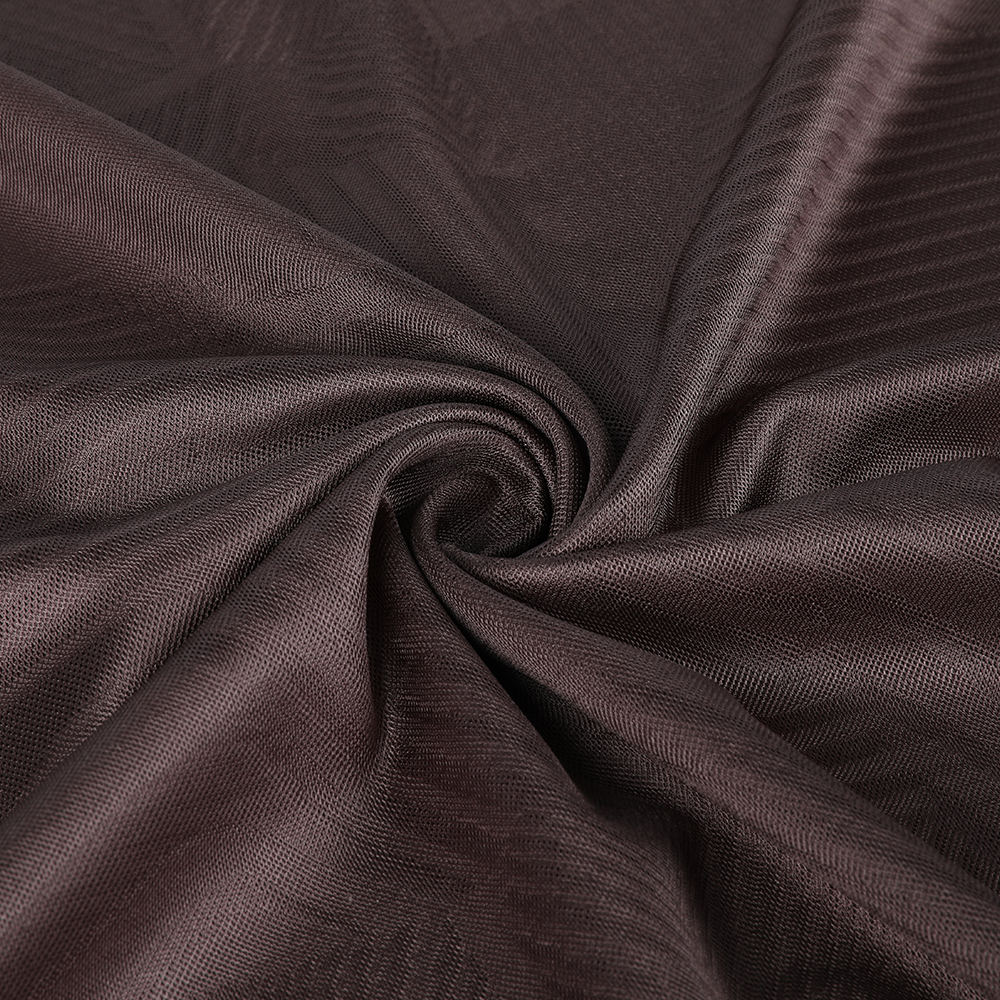

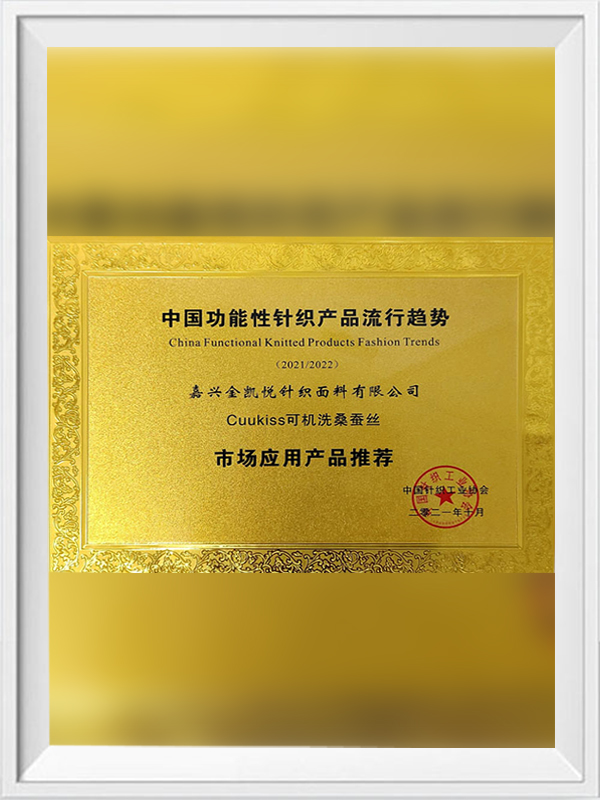

Mulberry silk, known as the "Queen of Fibers", is a high-quality natural fiber fabric. It is famous for its lightness, softness, smoothness, breathability, and high-grade luster. It is comfortable and cool to wear and has a protective effect on the skin. Promote skin metabolism and keep it smooth and moisturized. Mulberry silk can effectively absorb ultraviolet rays and protect the skin from damage. The material is delicate and easy to damage, especially after washing, it is easy to get lint and turn white, so it needs careful care. To solve this problem, after years of research and development, we have successfully launched CUUKISS machine washable mulberry silk fabric. This fabric uses high-tech means to scientifically process the polymer structure of mulberry silk, which significantly improves its wear resistance and greatly improves problems such as whitening and scratches after washing. After repeated standard washing, the fabric can remain as bright as new, fully meeting or exceeding machine washable standards. This innovative breakthrough greatly facilitates people's lives. Mulberry silk clothing no longer needs to be hand washed or dry cleaned but can be machine washed directly, thus saving a lot of time and energy and providing strong support for the wide application of mulberry silk fabrics.

-

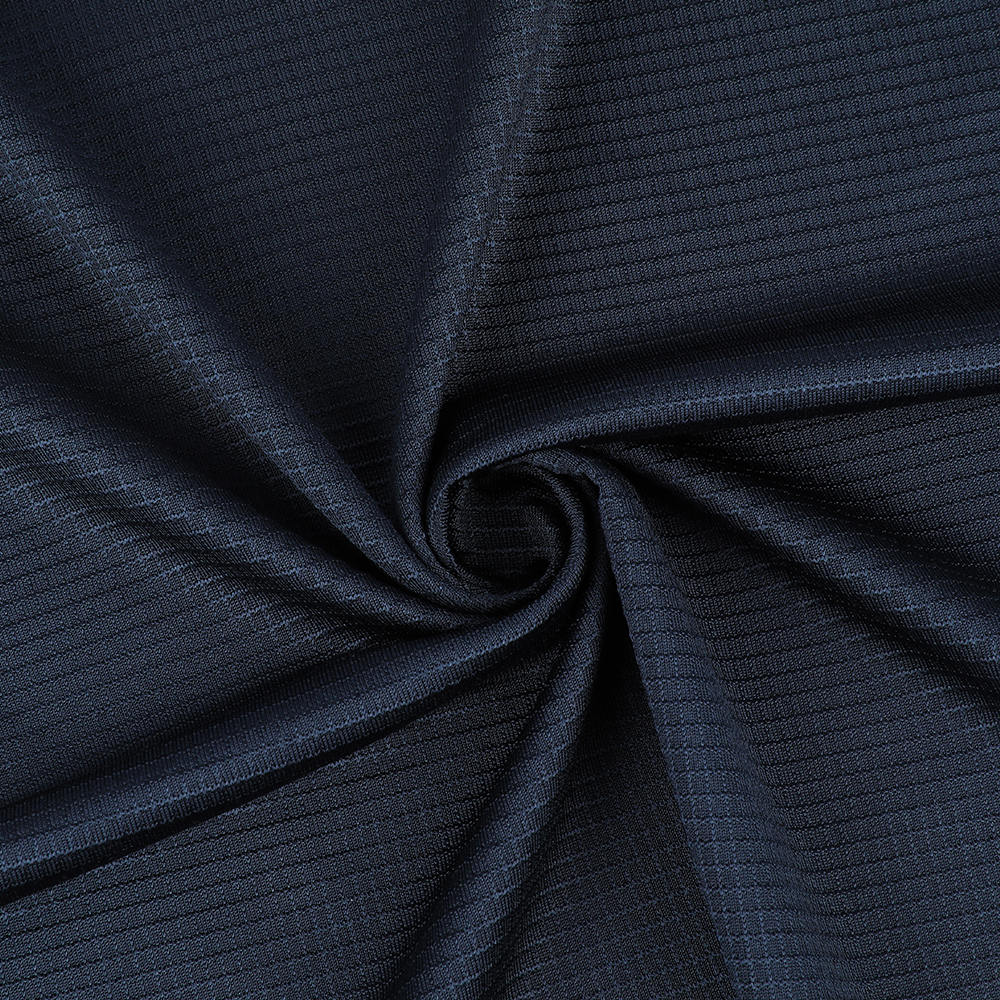

Comfortable Breathable Single-sided Jacquard Eco-friendly Silk Fabric for Business Clothing

-

Machine Washable Luxury Eco-friendly Knitted Mulberry Silk Fabric

-

Single-sided Jacquard Eco-friendly Machine Washable Knitted Mulberry Silk Fabric

-

Double-sided Jacquard Luxury Eco-friendly Machine Washable Business Clothing Silk Fabric

-

Comfortable and Breathable Single-sided Jacquard Silk Business Clothing Fabric

-

Machine Washable Silk Double-sided Jacquard Luxury and Delicate Business Clothing Silk Fabric

-

Machine Washable Silk Soft and Breathable Double-sided Jacquard Luxury Eco-friendly Mulberry Silk Business Clothing Fabric

-

Machine Washable Silk Double-sided Jacquard Silk Business Clothing Fabric

-

Machine Washable Silk Double-sided Jacquard Breathable And Eco-friendly Business Clothing Silk Fabric

-

Luxury Eco-friendly Machine Washable Silk Business Clothing Fabric

-

Machine Washable Silk Single-sided Jacquard Business Mulberry Silk Clothing Fabric

-

-

For apparel manufacturers and brand owners, the decision of where and how to source cotton shirt fabric wholesale is a fundamental strategic choice that directly impacts product quality, cost structure, brand reputation,...

READ MORE -

In the global garment industry, the challenge for engineers lies in balancing aggressive cost targets with the mechanical durability required for consumer satisfaction. The production of cheap knit fabric often carries a...

READ MORE

How to achieve Machine Washable Mulberry Silk Fabric through special processing technology?

In the textile industry, mulberry silk is known as the "Queen of Fibers" for its lightness, softness, smoothness, breathability and high-end luster. This high-quality natural fiber fabric is not only comfortable and cool to wear, but also has a protective effect on the skin. It can also effectively absorb ultraviolet rays and protect the skin from damage. However, mulberry silk is delicate and fragile, especially it is easy to pilling and whitening after washing, and needs careful care. This feature limits the wide application of mulberry silk fabrics to a certain extent.

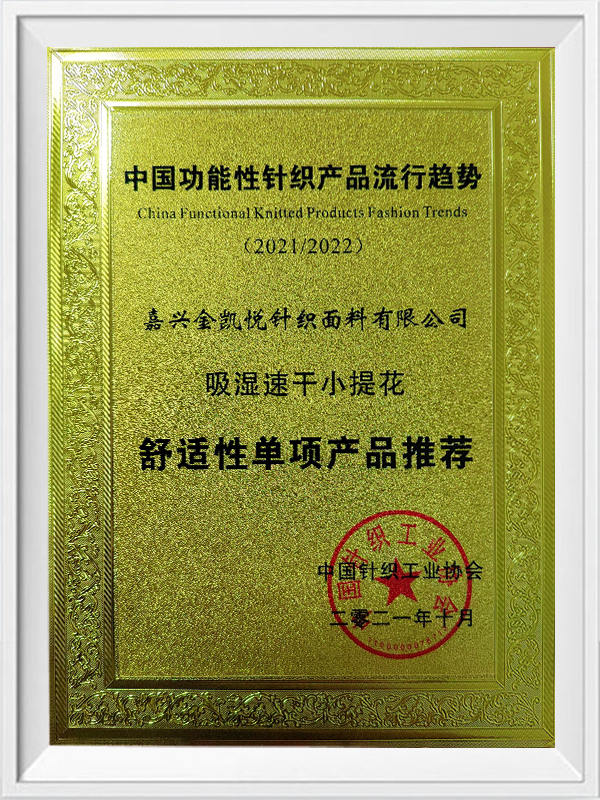

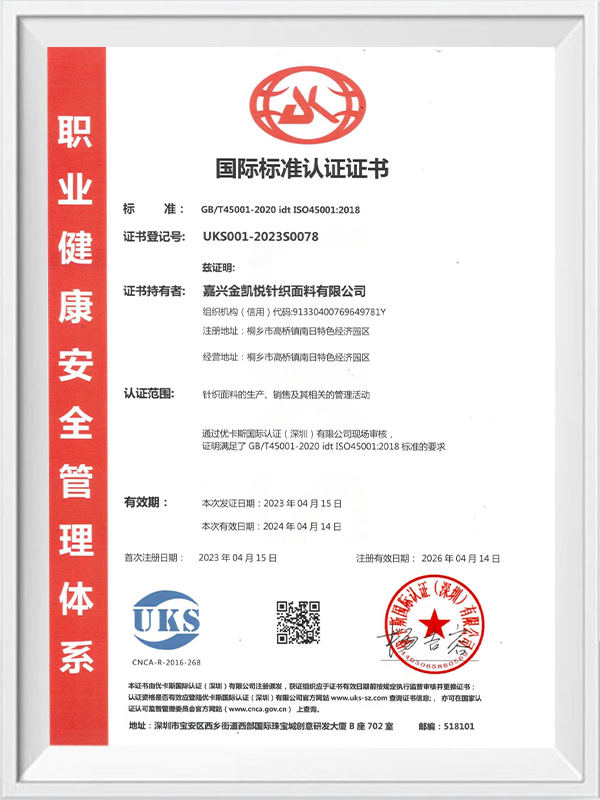

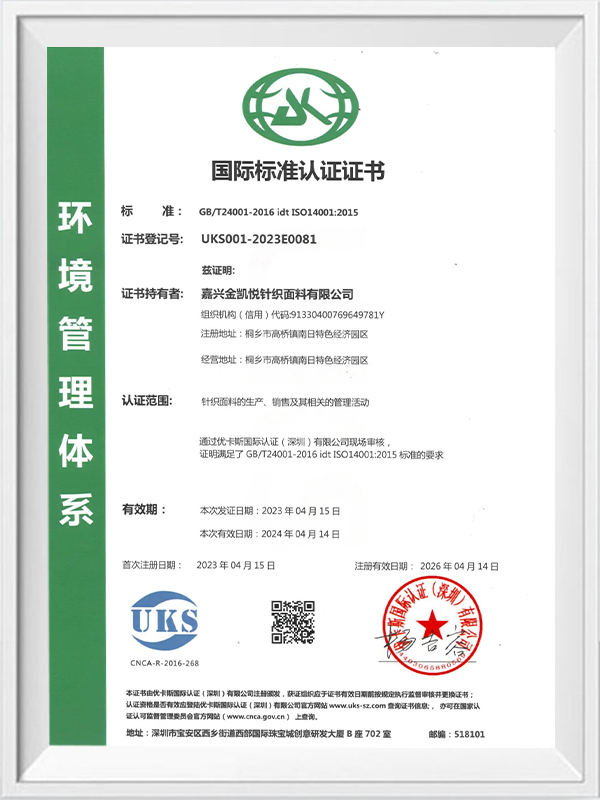

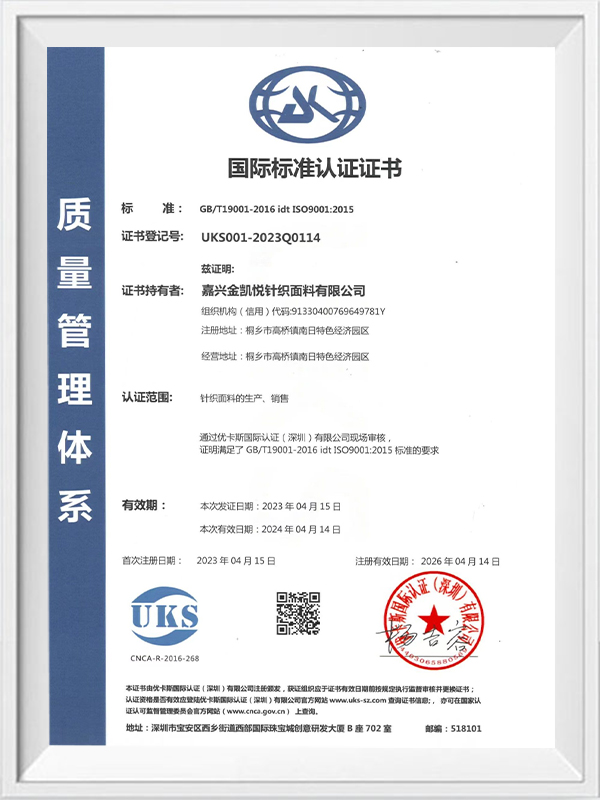

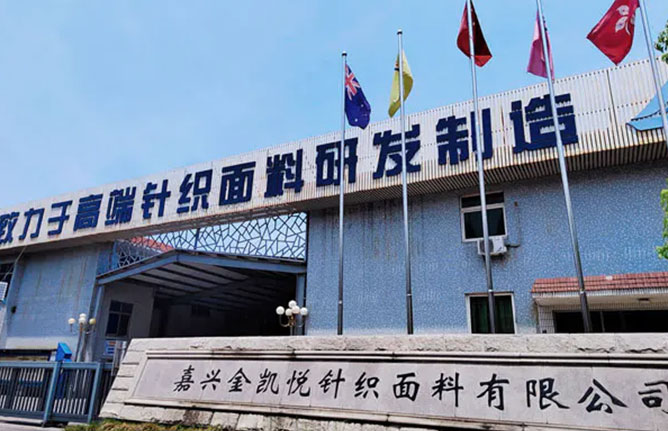

As Jiaxing Jinkaiyue knitted Fabric Co., Ltd., we are well aware of this industry pain point and are committed to solving this problem through technological innovation. After years of research and development, we have successfully launched Machine Washable Silk Knitting Fabric. This innovative breakthrough has greatly facilitated people's lives.

So, how did we achieve machine-washable mulberry silk fabrics through special processing technology?

The key lies in our scientific treatment of the polymer structure of mulberry silk. Through high-tech means, we have enhanced the wear resistance of mulberry silk, which greatly improves the problems of whitening and scratches after washing. After multiple standard washes, the fabric can still remain bright and new, fully meeting or exceeding the machine washable standard. The successful application of this technology means that Mulberry Silk Knitting Fabric no longer needs to be hand washed or dry cleaned, and can be directly machine washed, saving a lot of time and energy.

we are very strict in the selection of raw materials, covering a variety of fiber blends such as mulberry silk, cotton, wool, cashmere, polyester, and linen. Our circular machine types can adapt to various different knitting structures of single-sided knitting and double-sided knitting, from plain weave to complex high-pile weave, etc., which can be easily dealt with.

In terms of intelligent manufacturing, we are also in a leading position. We have the world's most advanced equipment and provide soft, durable and high-quality fabrics through unique liquid ammonia finishing technology. Liquid ammonia finishing is a textile treatment process that uses liquid ammonia to enhance the performance of the fabric, mainly to improve the strength, softness and appearance of the fabric. The application of this technology makes our fabrics excellent in softness, strength, wrinkle reduction, dye affinity and moisture absorption.

we also have a professional R&D team, accounting for about 20% of the total number of employees in the company. They are committed to the research and development, technology and design of new products to ensure that our products always remain at the forefront of the industry. In order to ensure product quality, we have invested in the introduction of advanced equipment from Italy, Germany, Switzerland, Japan, Taiwan and other places, and established a strict quality management system. From the inspection of fabrics during the production process to the shipment of goods, every link is strictly controlled by professional quality management personnel.

English

English 日本語

日本語 中文简体

中文简体