For apparel brand developers, textile engineers, and strategic procurement specialists, the choice between knit and woven fabrics is a foundational decision impacting product performance, consumer satisfaction, and brand...

READ MORECustom Jacquard Shirt Fabric

Cotton-polyester shirt fabric combines the dual advantages of cotton and polyester. It not only retains the natural skin-friendliness and breathability of pure cotton, but also cleverly integrates the wear resistance, wrinkle resistance, and quick-drying characteristics of polyester, making each shirt a classic choice in your wardrobe. The cotton part is derived from nature, delicate and soft, and can effectively absorb sweat and keep the skin dry. Even in the hot summer, you can feel the coolness and comfort of the breeze. Its natural fiber structure gives the fabric good breathability and warmth retention, which is suitable for all seasons, whether it is a daily leisure or business office, it can be easily controlled. The addition of polyester greatly improves the durability and practicality of the fabric. With its good elastic recovery and wrinkle resistance, polyester fiber ensures that the shirt can remain crisp and stylish after multiple washing and wearing, and is not easy to deform, reducing the trouble of ironing, and making your life more convenient and efficient. At the same time, the quick-drying characteristics of polyester allow clothes to quickly recover dryness in a humid environment, whether it is outdoor adventure or rainy travel, it can stay fresh and comfortable.

-

Sesame-point Crisp Breathable Jacquard Crisp Shirt Fabric

-

Single-sided Large Jacquard Crisp Sea Island Cotton Shirt Fabric

-

Double-sided Jacquard LA Breathable Eco-friendly Shirt Clothing Fabric

-

Single-sided Large Jacquard Crisp Sea Island Cotton Shirt Fabric

-

Crisp and Comfortable Single-sided Large Jacquard Shirt Fabric

-

Sesame-point Crisp Striped Jacquard Shirt Fabric

-

Sesame-point Easy-care LA Breathable and Comfortable Striped Cotton-Polyester Jacquard Shirt Fabric

-

-

For apparel manufacturers and brand owners, the decision of where and how to source cotton shirt fabric wholesale is a fundamental strategic choice that directly impacts product quality, cost structure, brand reputation,...

READ MORE -

In the global garment industry, the challenge for engineers lies in balancing aggressive cost targets with the mechanical durability required for consumer satisfaction. The production of cheap knit fabric often carries a...

READ MORE

How to control the shaping process of cotton-polyester shirt fabric to ensure the dimensional stability and appearance quality of the fabric?

Cotton-polyester shirt fabric has become a leader in the modern clothing market with its unique material combination - the warmth and skin-friendliness of cotton and the toughness and durability of polyester. This fabric not only gives the wearer an excellent comfort experience, but also ensures the lasting shape and easy-care characteristics of the clothing. However, to give full play to these advantages of knitted large jacquard fabric, it is necessary to strictly control the shaping process during the fabric production process to ensure the dimensional stability and appearance quality of the fabric.

Key elements of shaping process

1. Temperature control

Temperature is one of the core elements in the shaping process. For cotton-polyester blended fabrics, reasonable temperature setting can effectively promote the cross-linking reaction between fibers and enhance the stability of the fabric. Too high or too low temperature may have an adverse effect on the fabric. For example, too high temperature may cause the fabric to turn yellow and lose strength, while too low temperature cannot achieve the ideal shaping effect. Therefore, during the shaping process, the temperature needs to be accurately set and adjusted according to the specific composition ratio of the fabric, the thickness of the yarn, and the expected performance of the finished product.

2. Tension management

Tension control is another key to ensure the dimensional stability of fabrics. On the setting machine, the fabric needs to be stretched to eliminate the internal stress during the production process, but at the same time, it is also necessary to avoid excessive stretching that causes the fabric to deform. Appropriate tension setting can maintain the uniformity of the fabric in terms of width and length, and prevent shrinkage, distortion and other problems. Through a precise tension control system, combined with the characteristics of the fabric, the best setting effect can be achieved.

3. Setting agent selection and application

The selection and use of setting agents are crucial to improving the setting effect and durability of fabrics. For cotton-polyester blended fabrics, setting agents that can combine with cotton fibers and are compatible with polyester fibers should be selected to ensure uniform and lasting setting effects. The concentration, dosage and application method (such as dipping, spraying) of the setting agent must be strictly tested to achieve the best setting effect without affecting the feel and breathability of the fabric.

4. Setting time and cooling

The length of the setting time directly affects the penetration and curing degree of the setting agent. Too short a setting time may lead to incomplete setting, while too long a setting time may cause the fabric to feel hard or over-crosslinked. In addition, the cooling process after setting should not be ignored, as it helps the setting agent to fix better and improve the dimensional stability of the fabric. The cooling rate should be moderate to avoid damage to the fabric caused by rapid temperature changes.

Appearance quality control

In addition to the above-mentioned dimensional stability control, the appearance quality should not be ignored. This includes the flatness, color uniformity, and flawlessness of the fabric. During the setting process, the surface of the fabric should be checked regularly to promptly detect and deal with any possible defects such as wrinkles, color difference, oil stains, etc. At the same time, reasonable equipment maintenance and cleaning are also important measures to ensure the appearance quality of the fabric.

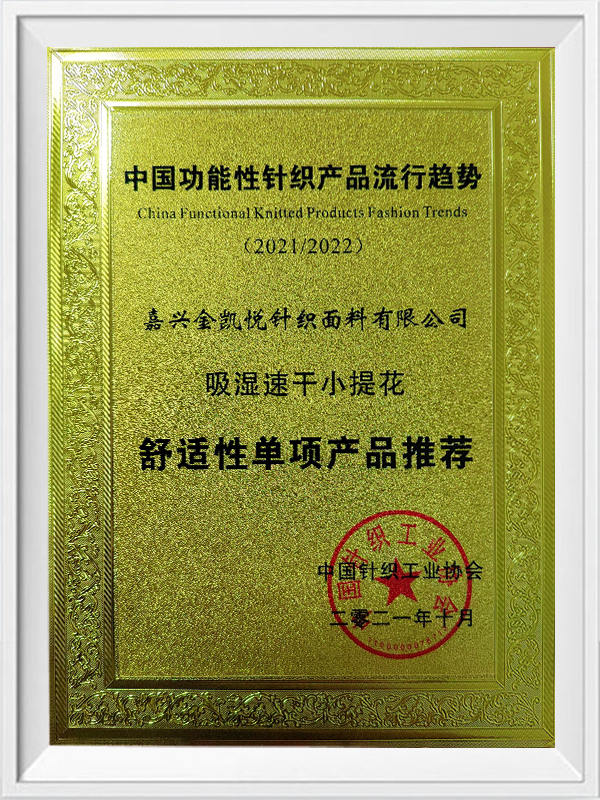

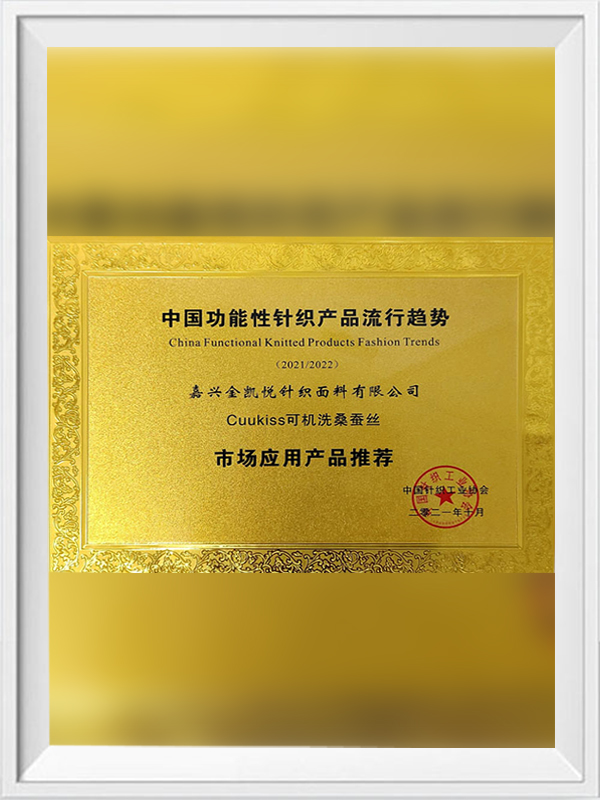

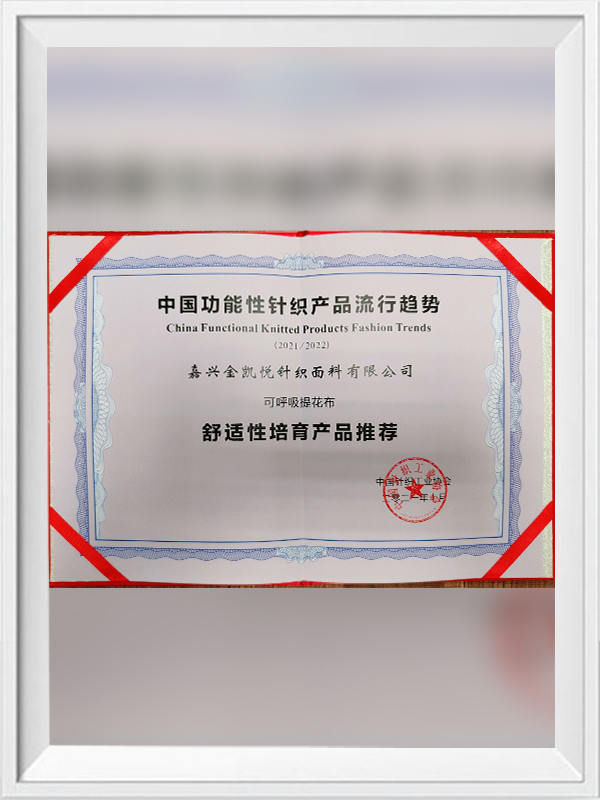

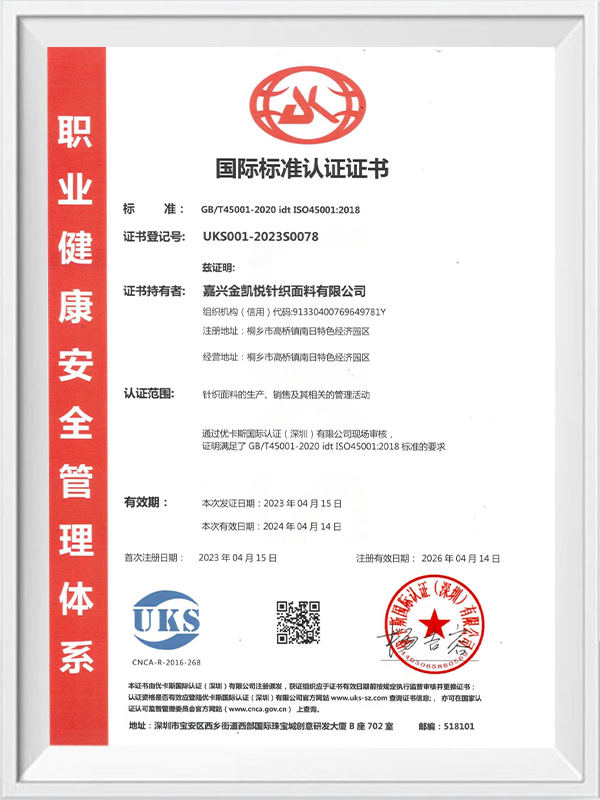

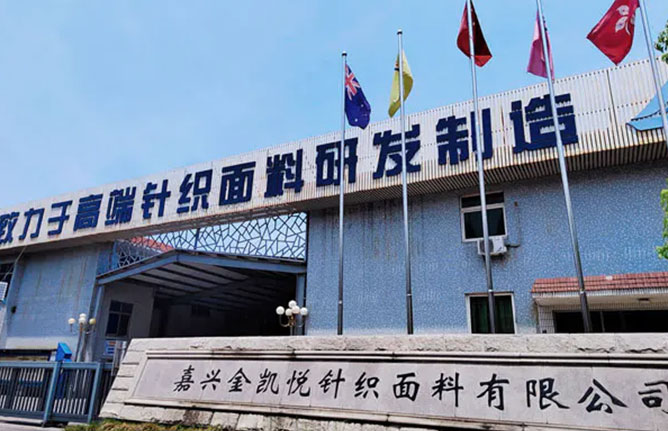

Jiaxing Jinkaiyue Knitted Fabric Co., Ltd. is well aware of the importance of the setting process for the quality of cotton polyester shirt fabrics. The company is equipped with advanced setting equipment, combined with a strict temperature, tension, setting agent and time control system to ensure that each batch of fabrics can achieve the best setting effect. At the same time, the company has a professional quality management team that strictly monitors the entire process from raw material procurement to finished product delivery to ensure that the fabrics meet high standards in dimensional stability and appearance quality.

English

English 日本語

日本語 中文简体

中文简体