For apparel brand developers, textile engineers, and strategic procurement specialists, the choice between knit and woven fabrics is a foundational decision impacting product performance, consumer satisfaction, and brand...

READ MOREWholesale High-Elastic knitted Shirt Fabric

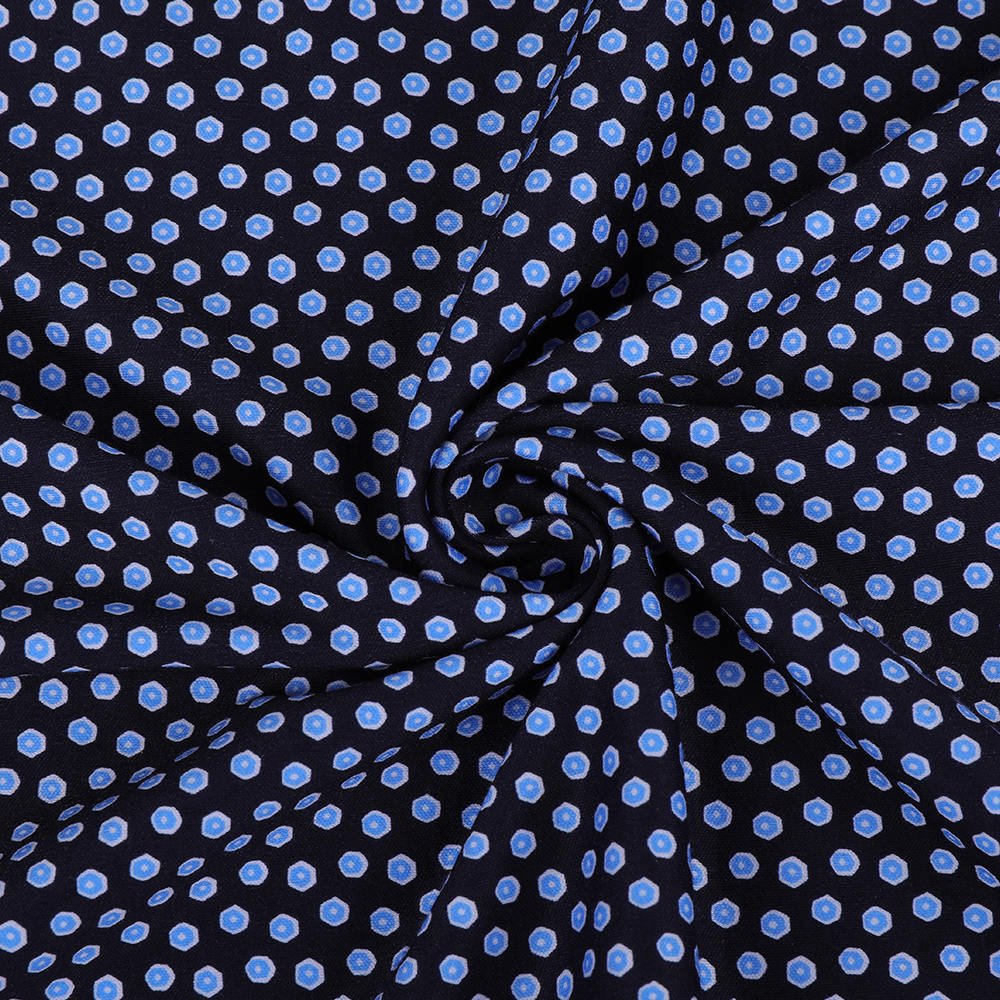

The good combination of high-quality natural fibers and high-tech synthetic fibers not only retains the softness, comfort, and good breathability of natural fibers, but also has the advantages of toughness, durability, and non-deformation of synthetic fibers. Whether it is delicate cotton, smooth silk, or elastic spandex, they are all carefully selected and proportioned to ensure that the quality of the fabric reaches the top level. The unique knitting structure gives the fabric a rich sense of layering and three-dimensionality. Whether it is a simple solid color design or an exquisite jacquard or printed pattern, it can show fashion and personality. Using advanced knitting technology, each yarn is tightly interwoven to form a uniform and delicate texture. The exquisite dyeing process makes the color bright and lasting, and it is not easy to fade. At the same time, after special treatment, the fabric has the properties of wrinkle resistance and shrinkage resistance, so that you can always maintain a neat and decent image. The good breathability of high-end knitted shirt fabrics allows the skin to breathe freely, and you will not feel stuffy even in hot weather. At the same time, moderate elasticity makes it more comfortable to wear and will not restrict your movements.

-

Cotton Environmentally Friendly Breathable And Comfortable Digital Printing Shirt Clothing Fabric

-

Double Jacquard Soft Skin-friendly Silk Cotton Shirt Fabric

-

Sesame-point Easy-care LA Breathable and Comfortable Striped Cotton-Polyester Jacquard Shirt Fabric

-

Spandex Jersey Skin-friendly Soft Silk Cotton Striped LA Shirt Fabric

-

Striped Comfortable Silk Cotton Shirt Fabric

-

Comfortable Breathable Environmentally Friendly Digital Printing Cotton Shirt Fabric

-

Breathable Eco-friendly Comfortable Silk Cotton LA Jacquard Shirt Fabric

-

Adjusted Jacquard Comfortable Breathable Eco-friendly Silk Cotton LA Shirt Fabric

-

-

For apparel manufacturers and brand owners, the decision of where and how to source cotton shirt fabric wholesale is a fundamental strategic choice that directly impacts product quality, cost structure, brand reputation,...

READ MORE -

In the global garment industry, the challenge for engineers lies in balancing aggressive cost targets with the mechanical durability required for consumer satisfaction. The production of cheap knit fabric often carries a...

READ MORE

How to design knitted structure to give fabrics a rich sense of layering and three-dimensionality while ensuring the elasticity and stability of high-elastic knitted shirt fabrics?

The design of knitted structure is the key to giving fabrics a rich sense of layering and three-dimensionality and ensuring the elasticity and stability of fabrics. In the field of knitted clothing, especially in the design of high-elastic knitted shirts, this requirement is particularly strict.

1. Principles of knitted structure design

When designing knitted structures, the first thing to be clear is the application scenarios and wearing needs of fabrics. For high-elastic knitted shirts, it is necessary to meet the comfort of daily wear and have a certain sense of fashion and three-dimensional effect. Therefore, the design principles should revolve around the following aspects:

Elasticity and stability: ensure that the fabric can quickly return to its original shape after stretching while maintaining the stability of the structure.

Layering and three-dimensional sense: achieve the multi-layer and three-dimensional effect of fabrics through different weaving methods and yarn combinations.

Breathability and hygroscopicity: considering the wearing comfort of shirts, knitted structures should have good breathability and hygroscopicity.

2. Specific implementation methods

Double-layer and triple-layer knitted structure design

Double-layer structure: through the cooperation of the front and rear needle beds of the flat knitting machine, two overlapping layers of fabric tissue are woven. This structure not only increases the thickness and stability of the fabric, but also achieves rich concave and convex textures and color contrasts through different weaving methods (such as air layer combined with air-lift weaving technology), thus giving the fabric a three-dimensional feel.

Three-layer structure: On the basis of the double-layer structure, the third layer structure is formed by adding fillers. This design not only further enhances the stability and elasticity of the fabric, but also achieves a variety of three-dimensional effects through different materials and shapes of fillers.

Yarn selection and combination

Combined weaving of yarns of different materials, colors and thicknesses can create rich color layers and texture effects. For example, blending spandex with other fibers can increase the softness and comfort of the fabric while ensuring elasticity.

Weaving method and pattern design

Different weaving methods (such as plain, twill, rib, etc.) and pattern designs (such as geometric figures, animal and plant patterns, etc.) can enrich the visual effect and layering of the fabric. At the same time, by changing the weaving density and needle method, the elasticity and stability requirements of the fabric in different parts can also be achieved.

3. Case Analysis

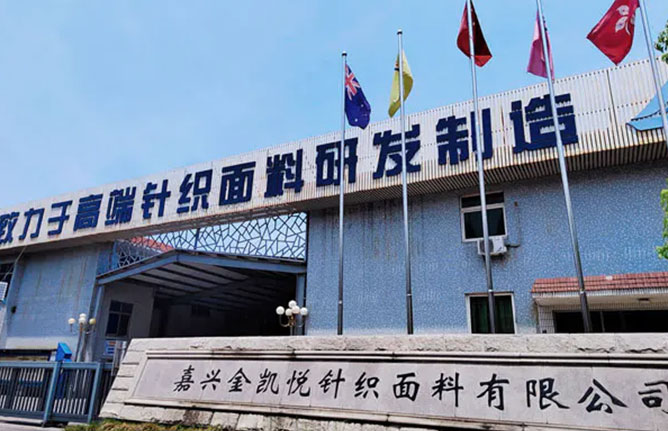

Jiaxing Jinkaiyue Knitted Fabric Co., Ltd. has accumulated rich experience in the design and production of high-elastic knitted shirt fabrics. The company has a team of about 300 people, 20% of whom are engaged in R&D, technology and design. To ensure product quality, the company has introduced advanced equipment from Italy, Germany, Switzerland, Japan, Taiwan and other places, which not only improves production efficiency, but also provides more possibilities for the design of knitted structures.

Take a high-elastic knitted shirt fabric of the company as an example. The fabric adopts a double-layer knitted structure design. The front and rear needle beds are knitted with yarns of different colors, forming a sharp color contrast and layering. At the same time, the concave and convex texture and three-dimensional effect of the fabric are achieved through the air layer combined with air-raising knitting technology. In terms of yarn selection, the company selected high-quality spandex yarn blended with other fibers to ensure the elasticity and comfort of the fabric. In addition, the company also fine-tuned the knitting density and needle method according to the needs of different parts of the shirt to ensure the overall stability and local elasticity of the fabric.

Through reasonable knitting structure design, yarn selection and combination, weaving method and pattern design, the fabric can be given a rich sense of layering and three-dimensionality, while ensuring the elasticity and stability of high-elastic knitted shirt fabrics. Jiaxing Jinkaiyue Knitted Fabric Co., Ltd. has achieved remarkable results in this field. Its advanced production equipment and professional R&D team provide strong guarantees for the production of high-quality knitted fabrics.

English

English 日本語

日本語 中文简体

中文简体