For apparel brand developers, textile engineers, and strategic procurement specialists, the choice between knit and woven fabrics is a foundational decision impacting product performance, consumer satisfaction, and brand...

READ MOREWholesale Knitted Wool And Cashmere Blended Knitting Fabric

Knitted wool fabric is known for its good warmth and comfort, making it ideal for winter clothing. The natural characteristics of wool give it good thermal insulation capabilities, which can effectively resist the severe cold outside and provide continuous warmth and care. The texture of the fabric is soft and fluffy, and it has no friction when in contact with the skin, bringing the ultimate comfortable experience and suitable for long-term wear and activities. Wool fabric has good elasticity and can expand and contract freely with body movements, ensuring that it can be worn freely without affecting the convenience of movement. The company uses machine-washable technology developed over ten years to make knitted wool fabrics with ultra-high anti-pilling and anti-shrink properties, making them easy to care for and improving product durability. This fabric not only maintains the high-end texture of wool but also solves the problems of traditional wool fabric care, showing good comprehensive performance. Knitted wool fabric has become the fabric of choice for winter clothing due to its warmth, comfort, good elasticity, and easy care, providing consumers with a high-quality wearing experience.

-

-

For apparel manufacturers and brand owners, the decision of where and how to source cotton shirt fabric wholesale is a fundamental strategic choice that directly impacts product quality, cost structure, brand reputation,...

READ MORE -

In the global garment industry, the challenge for engineers lies in balancing aggressive cost targets with the mechanical durability required for consumer satisfaction. The production of cheap knit fabric often carries a...

READ MORE

Are environmentally friendly materials or processes used to produce this Knitted Wool And Cashmere Blended Knitting Fabric ?

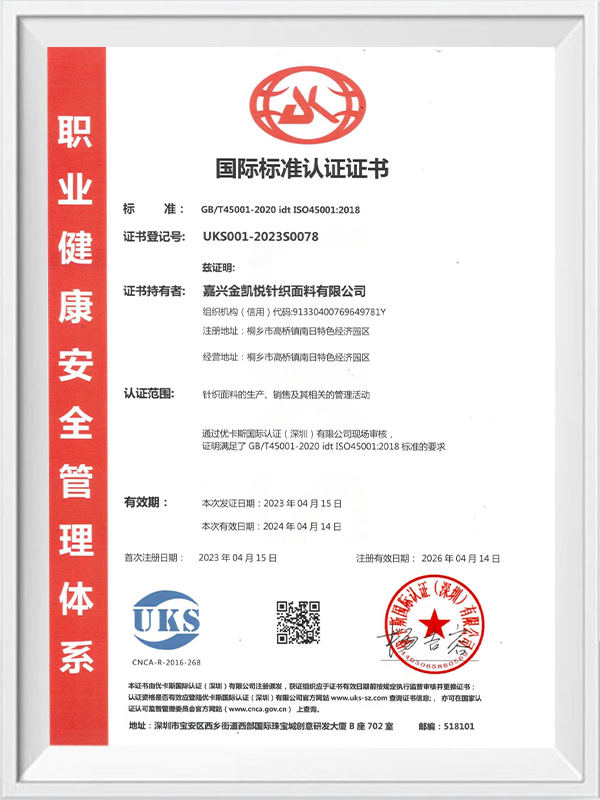

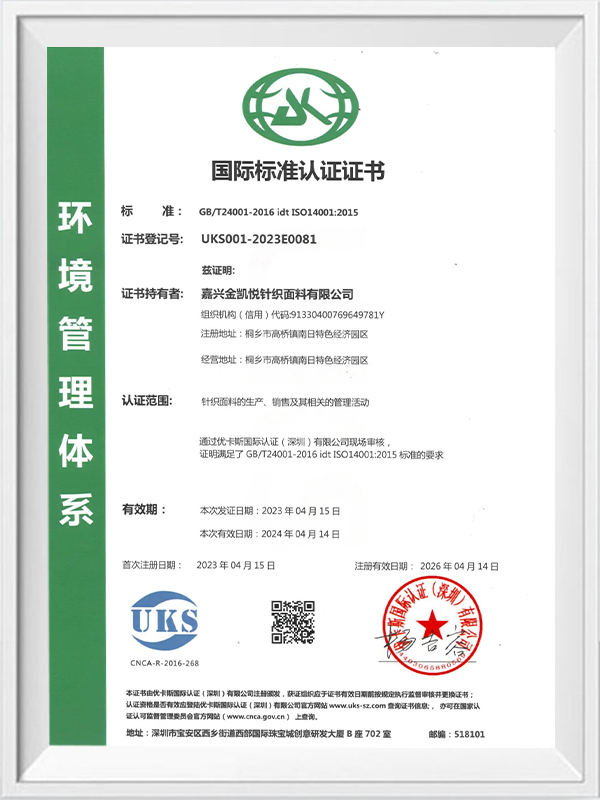

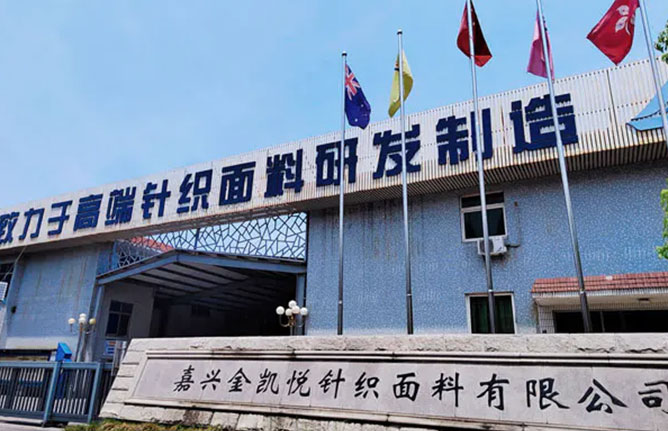

At Jiaxing Jinkaiyue knitted Fabric Co., Ltd., we are well aware of the importance of environmental protection and sustainable development, so when producing our Knitted Wool Fabric, we always take environmentally friendly materials and processes as the core consideration.

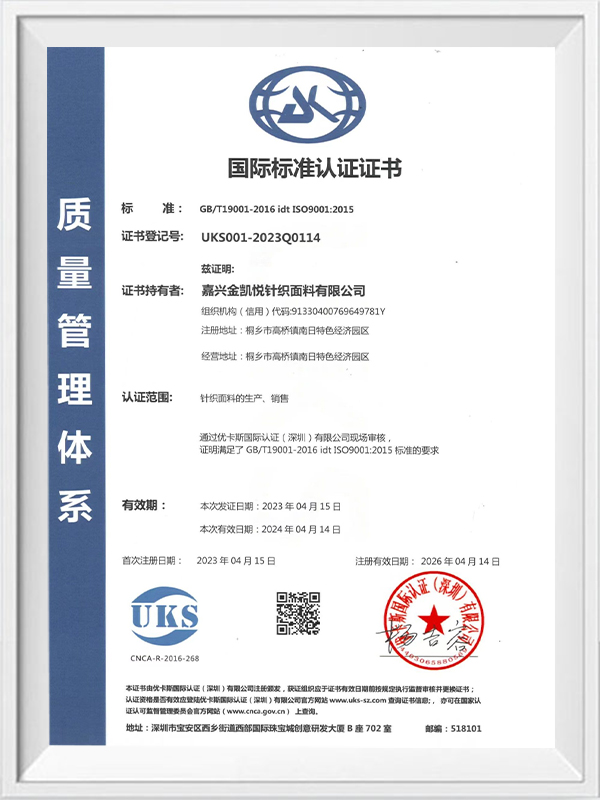

We have a strict quality management system for textile quality, and every link from the selection of raw materials to the production process is carefully planned and strictly controlled. Our professional quality management personnel check the fabrics from the production process until the goods are shipped to ensure that every product meets our high standards.

In terms of raw material selection, we at Jiaxing Jinkaiyue knitted Fabric Co., Ltd. are committed to selecting environmentally friendly materials. As a manufacturer of high-end knitted fabrics, our raw materials cover a variety of fiber blends such as mulberry silk, cotton, wool, cashmere, polyester, and linen. In the selection of these raw materials, we always adhere to the principle of environmental protection and give priority to sustainable and renewable fibers to reduce the impact on the environment.

we use internationally advanced equipment, such as advanced circular knitting machines, which can weave a variety of knitting types, including single-sided knitting and double-sided knitting. Our R&D team is constantly researching new knitting technologies to improve the functionality and aesthetics of fabrics. During the R&D process, we focus on adopting environmentally friendly processes to reduce the environmental burden of the production process by optimizing production processes, reducing waste generation, and improving energy efficiency.

Take our Coarse Needle Wool Fabrics as an example. This fabric is known for its good warmth retention and comfort, making it an ideal choice for winter clothing. The natural characteristics of wool give it good warmth retention, which can effectively resist the cold outside and provide continuous warm care. The fabric is soft and fluffy, and there is no friction when it comes into contact with the skin, bringing an extremely comfortable experience. We use machine washable technology developed for more than ten years to make knitted wool fabrics have super high anti-pilling and anti-shrinkage properties, easy to care for, and improve product durability. The development and application of this technology not only improves the overall performance of the product, but also reflects our commitment to environmental protection and sustainable development.

Our circular knitting machines can adapt to various knitting structures of single-sided and double-sided knitting, from plain weave, rib weave, jacquard weave to complex high-pile weave, single blister weave, loop transfer weave, lanceolate weave, round eyelet weave, Swiss emboss weave, six-row Roman knitting, etc. Our product line is rich and diverse, meeting the needs of different customers.

In the process of producing blended fabrics, Jiaxing Jinkaiyue knitted Fabric Co., Ltd. always adheres to the concept of environmental protection, selects environmentally friendly materials, adopts environmentally friendly processes, promotes circular economy, and conducts employee training, striving to achieve the dual goals of high-end knitted fabric production and sustainable development.

English

English 日本語

日本語 中文简体

中文简体