For apparel brand developers, textile engineers, and strategic procurement specialists, the choice between knit and woven fabrics is a foundational decision impacting product performance, consumer satisfaction, and brand...

READ MORECustom Wool Polyester Fabrics

Wool-polyester fabric combines the warmth and comfort of natural fibers with the durability and easy-care properties of synthetic fibers. The fabric is a blend of selected wool and high-strength polyester fibers. It not only maintains the natural advantages of wool such as warmth, breathability, moisture absorption, and perspiration removal, but also incorporates the practical characteristics of polyester such as wrinkle resistance, wear resistance, and easy care, achieving complementary and optimized performance. The wool-polyester fabric has good color expression and fastness can adapt to diverse designs and personalized needs, and is widely used in business formal wear, casual wear, and home decoration. It has strong wrinkle resistance and good elastic recovery. Even if it is worn for a long time or washed frequently, it can keep the clothes flat and crisp, greatly reducing the complexity of daily care. With its unique blending advantages, wool-polyester fabric shows good comprehensive performance, becoming an ideal choice for consumers who pursue a high-quality life and professional image, reflecting the good combination of modern textile technology and natural materials.

-

-

For apparel manufacturers and brand owners, the decision of where and how to source cotton shirt fabric wholesale is a fundamental strategic choice that directly impacts product quality, cost structure, brand reputation,...

READ MORE -

In the global garment industry, the challenge for engineers lies in balancing aggressive cost targets with the mechanical durability required for consumer satisfaction. The production of cheap knit fabric often carries a...

READ MORE

How to control the blending ratio of wool polyester fabrics? Are the blended fibers specially treated to enhance spinnability?

The blending ratio of wool polyester fabrics is directly related to the performance and application areas of the final product. Reasonable blending ratio design needs to give full play to the complementary advantages of the two fibers on the basis of maintaining the original advantages of the fabric to achieve the best wearing experience and use effect.

Principles for selecting blending ratios

Performance demand orientation: Determine the blending ratio according to the final use of clothing or home decorations. For example, business formal wear pays more attention to the stiffness and wrinkle resistance of the fabric, which may increase the proportion of polyester fiber; while casual wear or household items may prefer the softness and breathability of wool, thereby appropriately reducing the content of polyester fiber.

Cost-effectiveness considerations: Wool, as a natural fiber, is relatively expensive, while polyester fiber is more economical. Reasonable blending ratios need to consider production costs while ensuring fabric quality to maximize cost-effectiveness.

Wearing comfort: The blending ratio also needs to consider the wearer's comfort, such as the warmth and breathability of wool, and the wrinkle resistance and easy-to-care nature of polyester fibers, which need to be balanced in the ratio setting.

Specific control of blending ratio

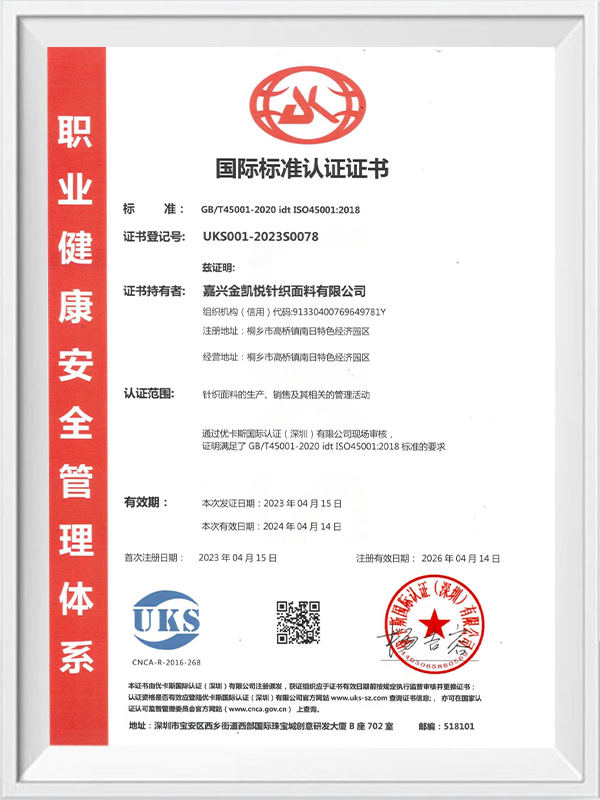

Raw material selection and proportioning: When producing wool-polyester fabrics, Jiaxing Jinkaiyue Knitted Fabric Co., Ltd. selects high-quality wool and high-strength polyester fibers as raw materials, and ensures that each batch of fabrics can reach the preset blending ratio through a precise proportioning system. The company uses advanced metering equipment to accurately weigh the raw materials to ensure the accuracy of the blending ratio.

Optimization of blending process: During the blending process, the company uses advanced blending technologies, such as air-flow blending and drawing blending, to ensure that wool and polyester fibers are evenly mixed at the fiber level to avoid fiber agglomeration and affect fabric performance. By adjusting the blending process parameters, such as blending temperature, humidity, speed, etc., the blending effect is further optimized.

Testing and verification of blending ratio

Physical property test: After blending is completed, the physical properties of the fabric need to be tested, including tensile strength, tear strength, abrasion resistance, wrinkle resistance, etc., to verify whether the blending ratio achieves the expected effect.

Chemical property test: Check the color fastness, shrinkage, acid and alkali resistance and other chemical properties of the fabric to ensure that the fabric can remain stable under different environments.

Sensory evaluation: Through the sensory evaluation of experts or consumers, subjective judgments are made on the feel, gloss, breathability, etc. of the fabric, and the rationality of the blending ratio is comprehensively evaluated.

In order to improve the blending effect of wool polyester fibers and enhance the spinnability of the fabric, special treatment of the blended fibers is usually required. These treatments can not only improve the blending uniformity of the fibers, but also improve the overall performance of the fabric.

Pretreatment of wool

Anti-shrinkage treatment: Wool has a natural shrinkage property, which can easily cause the fabric to shrink and deform. Through chlorination or bio-enzyme treatment, the wool scale layer is destroyed, the shrinkage property is reduced, and the dimensional stability of the fabric is improved.

Softening treatment: Wool is pretreated with a softener to improve its feel, make it softer and smoother, and improve wearing comfort.

Antistatic treatment: Wool is prone to static electricity, which affects the wearing experience. By adding antistatic agents, static electricity can be effectively reduced and the skin-friendliness of the fabric can be improved.

Modification of polyester fiber

Fine denier treatment: Through chemical or physical methods, polyester fiber is refined to make it softer and more drapable. After blending with wool, the fabric is more delicate and light.

Hydrophilic modification: Polyester fiber itself has poor hydrophilicity. Hydrophilic groups are introduced through copolymerization, grafting and other methods to improve the moisture absorption and perspiration performance of the fiber, which complements the breathability of wool.

Anti-ultraviolet treatment: Anti-ultraviolet agents are added to polyester fibers to enhance their anti-ultraviolet ability and protect the wearer from ultraviolet damage. It is suitable for outdoor clothing.

Compatibility treatment of blended fibers

Interface compatibilizer: Use interfacial compatibilizer to treat blended fibers to improve the interfacial bonding between wool and polyester fibers and improve the uniformity and stability of blended fibers.

Plasma treatment: Use plasma technology to modify the surface of blended fibers, increase the active groups on the fiber surface, promote mutual penetration and bonding between fibers, and improve the blending effect.

English

English 日本語

日本語 中文简体

中文简体